Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

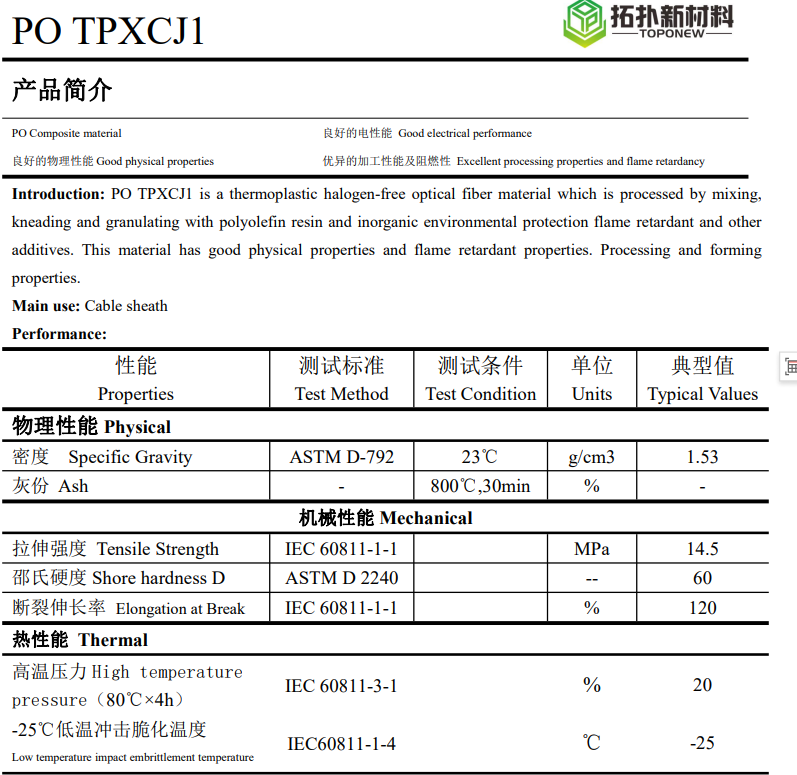

PO TPXCJ1

TPXCJ1 is a premium halogen-free thermoplastic optical fiber material specially designed for cable sheathing. Made by combining polyolefin resin, inorganic flame retardants, and other eco-friendly additives, it offers excellent physical, flame-retardant, and processing properties. Ideal for high-performance cable applications.

- Product Details

-

Download

Customizable Materials Available:

- Color (Customization of plastic pellet color according to your requirements.)

- Flame retardant grade (Let us know which flame retardant level you need: 0.8mm-3.0mm HB, V0, V1, V2, 5VA, 5VB)

- Glass fiber reinforcement material (10%-50% availability)

- Carbon fiber reinforcement material (10%-50% availability)

- UV resistance property (Tell us the application scenarios or UV resistance level of the materials )

- Other materials can also be customized ( Just need to provide your Technical Data Sheet. )

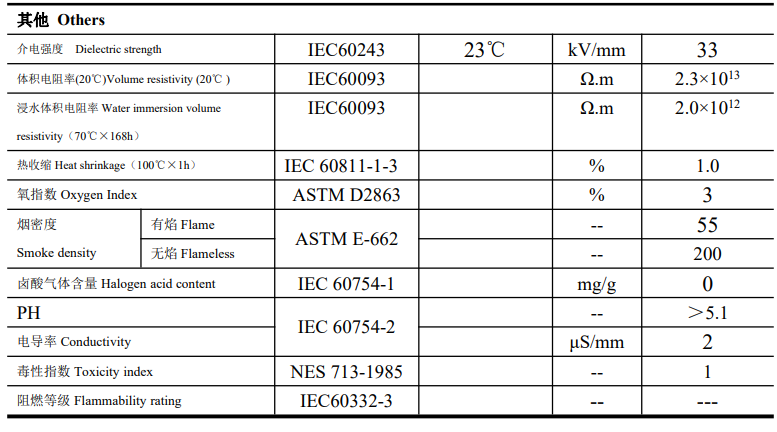

The Technical Data Sheet of PO TPXCJ1

Suzhou Topo New Material – PO TPXCJ1 Plastic Pellets

Introducing :TPXCJ1 is a high-performance thermoplastic halogen-free optical fiber material, which is refined by mixing, kneading and granulating polyolefin resin, inorganic environmentally friendly flame retardant and a variety of high-efficiency additives. The material has excellent flame retardant properties, excellent physical strength, and excellent processing and molding properties, making it an ideal choice for modern high-standard optical fiber cable sheathing.

Key Features:

Environmentally friendly and halogen-free:It does not contain halogen and complies with the requirements of international environmental protection regulations such as RoHS and REACH to avoid the release of harmful substances and ensure safety and environmental friendliness.

Efficient flame retardant:By adding high-quality inorganic flame retardants, the material has significant flame retardant effects and meets flame retardant standards such as IEC 60332-1 and UL 94 V-0, providing a high level of safety protection for optical fiber cables.

Excellent physical properties:Tensile strength: The material has excellent tensile properties and can withstand high external forces.

Wear-resistant and durable: Good wear resistance and surface stability extend the service life of the cable.

Low smoke and low toxicity: The smoke and toxic gases released in a fire are low, ensuring personal safety.

Excellent processing performance:Suitable for a variety of processing methods such as extrusion, injection molding and blow molding.

The material has excellent melt flow properties, is easy to operate, and reduces production difficulty.

Stable processability reduces waste and energy loss and improves production efficiency.

Wide temperature adaptability:It is suitable for a variety of ambient temperatures, meets the needs of harsh industrial environments, and ensures long-term stable operation of cables under high or low temperature conditions.

Applications:

Fiber optic cable jacket:As the outer sheath material of optical fiber cables, it provides insulation, weather resistance and mechanical protection for the cables.

Special cable applications:It is used in industries, communications, rail transit and other scenes with high requirements for flame retardancy and environmental protection.

Technical support: Provide professional technical guidance and application solutions according to customers' specific needs.

Sample service: Provide samples for testing.

Customization: Material performance parameters can be adjusted to meet the needs of different application scenarios.

Choose TPXCJ1 to provide a safer and more environmentally friendly solution for your fiber optic cable jacket!

For more information, please feel free to contact our sales team or visit the official website for details.

Download

-

PO TPXCJ1.pdf

Download PO TPXCJ1.pdf